BRANŻE:

Spożywcza

Spirytusowa

Browarnicza

Petrochemiczna

Mleczarska

Owocowo-warzywna

Farmaceutyczna

Produkcja Batchowa

Pigging Systems

Stacje CIP

Stanowiska załadunku cystern

Magazyny chemii

Pasteryzatory

Produkcja alkoholi: Inline, Batch

Produkcja Batchowa

Pigging Systems

Stacje CIP

Stanowiska załadunku i rozładunku cystern

Magazyny chemii

Pasteryzatory

▼

▼

▼

▼

▼

▼

SPAWALNICTWO:

Matryce zaworowe

Instalacje technologiczne

Trasy kablowe

Wymienniki ciepła

ELEKTRYKA:

Budowa szaf rozdzielniczych

Prefabrykacja rozdzielnic

Instalacje elektryczne

ELEKTRYKA:

Budowa szaf rozdzielniczych

Prefabrykacja rozdzielnic

Instalacje elektryczne

PROGRAMOWANIE:

Industry 4.0

Programowanie PLC

HMI

Systemy Rozproszone

Kalibracja urządzeń pomiarowych

Systemy Raportowania

Gromadzenie danych/Integracja systemów

Monitoring zużycia mediów

SCADA

Programowanie:

Industry 4.0

Programowanie PLC

HMI

Systemy Rozproszone

Kalibracja urządzeń pomiarowych

Systemy Raportowania

Gromadzenie danych/Integracja systemów

Monitoring zużycia mediów

SCADA

Pewnie i bezpiecznie!

Odkryj szeroką gamę naszych rozwiązań.

Oferujemy indywidualne rozwiązania w zakresie automatyzacji dla Twojej branży. Do każdego klienta podchodzimy indywidualnie.

Kilka naszych rozwiązań

PRODUKCJA INLINE

Magma InLine do nawet trzykrotnie krótszy czas produkcji.

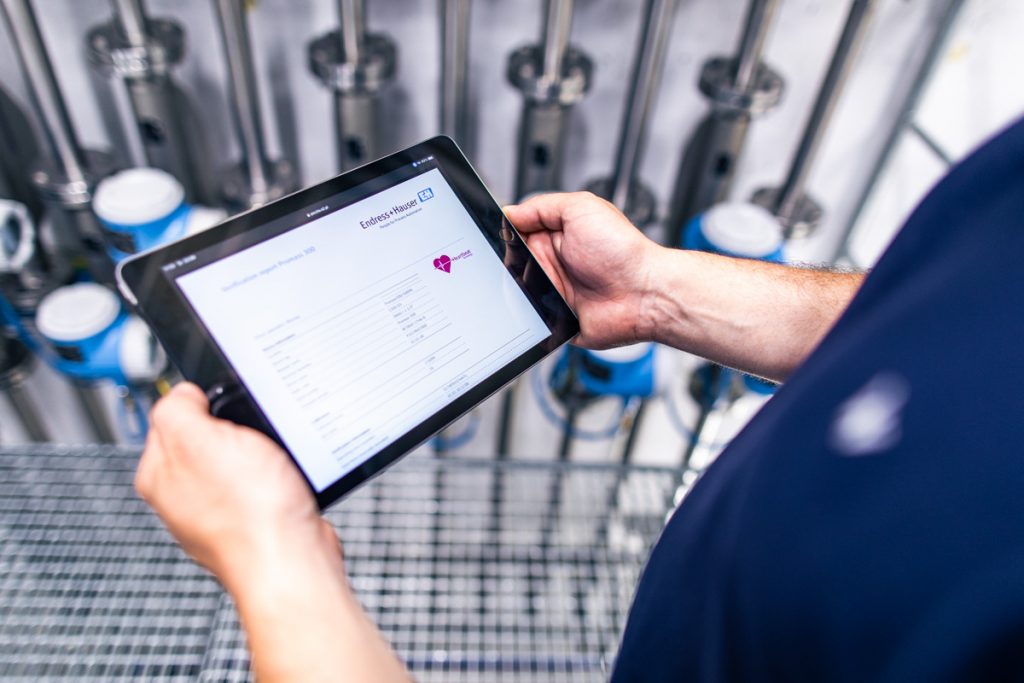

INDUSTRY 4.0

Jesteśmy w stanie pomóc w każdym aspekcie. Od czujników, przez sterowniki PLC aż po systemy Business Intelligence.

MATRYCA ZAWOROWA

Magma Matrix to efektywne rozwiązanie do maksymalizacji procesów przez zoptymalizowanie zarządzania przepływami.

Nestle Engineering Automation Toolbox czyli w skrócie NEAT to koncepcja opracowana dla Nestle przez Rockwell Automation.

INSTALACJE TECHNOLOGICZNE

Niezależnie czy jest to branża spożywcza, petrochemiczna, spirytusowa, farmaceutyczna, nasze instalacje spełnią nawet najwyższe oczekiwania.

INSTALACJE ELEKTRYCZNE

Dobrze przemyślana i wykonana instalacja elektryczna może zaoszczędzić w przyszłości wielu problemów.

Kilka naszych rozwiązań

PRODUKCJA INLINE

Magma InLine do nawet trzykrotnie krótszy czas produkcji.

INDUSTRY 4.0

Jesteśmy w stanie pomóc w każdym aspekcie. Od czujników, przez sterowniki PLC aż po systemy Business Intelligence.

MATRYCA ZAWOROWA

Magma Matrix to efektywne rozwiązanie do maksymalizacji procesów przez zoptymalizowanie zarządzania przepływami.

Tutaj tekst

INSTALACJE TECHNOLOGICZNE

Niezależnie czy jest to branża spożywcza, petrochemiczna, spirytusowa, farmaceutyczna, nasze instalacje spełnią nawet najwyższe oczekiwania.

INSTALACJE ELEKTRYCZNE

TUTAJ TEKST

W pracy staramy się kierować 3 prostymi wartościami:

Zaufanie

Wierzymy, że budując dobre relacje międzyludzkie jesteśmy w stanie zrobić więcej.

Innowacyjność

"Jeśli nic nie zmienisz, to nic się nie zmieni"

Jakość

Zawsze chcemy spełnić lub przekroczyć oczekiwania naszych klientów.

Dlaczego my?

- Instalacje wykonujemy kompleksowo

- Bogate, ponad 20-letnie doświadczenie

- Indywidualne i elastyczne podejście do klienta

- Pełen nadzór na każdym etapie realizacji projektu

- Przywiązujemy dużą wagę do szczegółów

Współpraca z nami jest bardzo prosta:

Otrzymujemy zapytanie

Twoje zapytanie trafia do odpowiedniego działu w naszej firmie.

Wizja lokalna

Nasi specjaliści odwiedzają Państwa zakład. Wymieniamy się spostrzeżeniami, przygotowujemy wstępną koncepcję, określamy budżet.

Oferta

Wycenę przygotowujemy szczegółowo, możesz być pewny, że nie zaskoczą Cię żadne dodatkowe koszty!

Prefabrykacja

Wszystko co możliwe, przygotowujemy w naszym warsztacie aby zredukować prace w Twojej fabryce do niezbędnego minimum.

Dostawa i montaż

Dostarczamy wcześniej przygotowany sprzęt. Przeprowadzamy sprawny montaż i okablowanie.

Uruchomienie

Nasi automatycy robią szybki IO Test i uruchamiają wcześniej przygotowany program.

Przekazanie dokumentacji

Żadna instalacja nie jest kompletna bez szczegółowej dokumentacji.

Serwis

Możesz spać spokojnie. Nasze instalacje są objęte gwarancją, a nawet po jej upływie nie zostawimy Cię samego!

Współpraca z nami jest bardzo prosta:

Otrzymujemy zapytanie

Twoje zapytanie trafia do odpowiedniego działu w naszej firmie.

Wizja lokalna

Nasi specjaliści odwiedzają Państwa zakład. Wymieniamy się spostrzeżeniami, przygotowujemy wstępną koncepcję, określamy budżet.

Oferta

Wycenę przygotowujemy szczegółowo, możesz być pewny, że nie zaskoczą Cię żadne dodatkowe koszty!

Prefabrykacja

Wszystko co możliwe, przygotowujemy w naszym warsztacie aby zredukować prace w Twojej fabryce do niezbędnego minimum.

Dostawa i montaż

Dostarczamy wcześniej przygotowany sprzęt. Przeprowadzamy sprawny montaż i okablowanie.

Uruchomienie

Nasi automatycy robią szybki IO Test i uruchamiają wcześniej przygotowany program.

Przekazanie dokumentacji

Żadna instalacja nie jest kompletna bez szczegółowej dokumentacji.

Serwis

Możesz spać spokojnie. Nasze instalacje są objęte gwarancją, a nawet po jej upływie nie zostawimy Cię samego!

Współpraca z nami jest bardzo prosta: